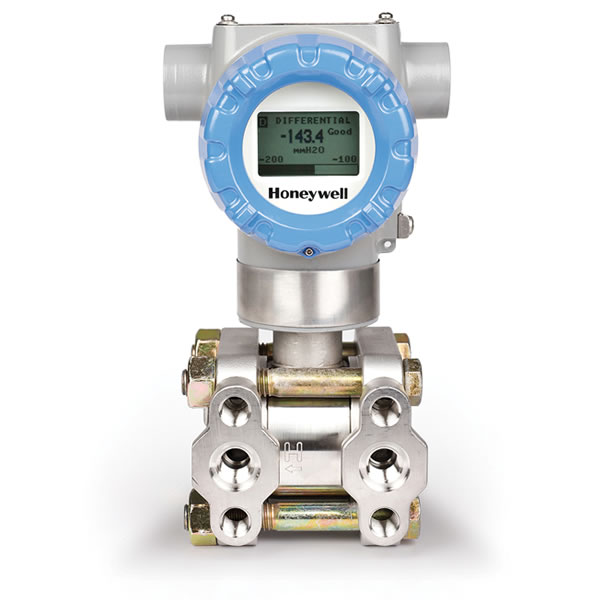

What Is It?

SmartLine Multivariable Transmitters can measure:

Differential pressure across a primary flow element such as an averaging pitot tube, venturi, flow nozzle, orifice plate, V-Cone®, wafer cone, wedge, etc.

Static process pressure from a single sensor

Process temperature from thermocouple or Resistance Temperature Detector (RTD) inputs.

The transmitters offer the following features:

-

Accuracy of up to 0.04% for differential pressure

-

Accuracy of up to 0.0375% for static pressure

-

Accuracy of up to 0.2°C for temperature

-

Mass flow accuracy of up to 0.6%

-

Built-in static pressure & temperature compensation

-

Rangeability of up to 400:1

-

Compensated flow response time of up to 2x per second

-

Multiple local display capabilities

-

Universal transmitter wiring

-

Modular design characteristics

-

Universal temperature input option

-

HART 7/DE protocol support

-

Built-in fail-safe feature for flow measurement.

How Does It Work?

SmartLine Multivariable Transmitters have a unique single capsule sensor design, with a piezoresistive sensor as the measuring means. The sensor contains a differential pressure sensor and an absolute or a gauge pressure sensor, providing highly accurate and stable measurements.

The flexible software of the transmitters further allows flow calculation for liquids, gases and steam. The flow calculation may include compensation of pressure and/or temperature as well as more complex variables such as viscosity, discharge coefficient, thermal expansion factor, velocity of approach factor, and gas expansion factor.

Digital integration with Honeywell control systems provides local measurement accuracy to the system level without adding typical analog-to-digital (A/D) and digital-to-analog (D/A) converter errors.

What Problems Does It Solve?

SmartLine Multivariable Transmitters combine integrated sensor and microprocessor technologies as well as dynamic flow compensation to produce the most accurate and consistent flow measurement possible. The transmitters help improve product yield and increase energy efficiency, while significantly lowering the total cost of ownership.

Smart

Smart